Engine Vacuum

About Engine Vacuum

-

Vacuum Measuring Units

- Vacuum is traditionally measured in inches of mercury and is really a measurement of pressure. For manifold vacuum you are measuring the difference in air pressure from the inside of the intake manifold, to the air pressure on the outside of the engine. Every change of two pounds per square inch of pressure will register as one inch of mercury or 1″hg on the vacuum gauge. If your engine is reading 20 inches of vacuum it is measuring a difference of 10 pounds per square inch between the inside of the intake manifold and outside air pressure.

-

What Affects Manifold Vacuum

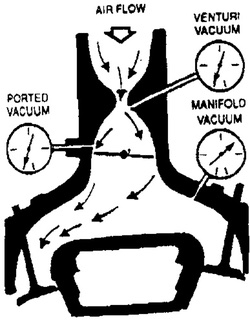

- A primary factor in manifold vacuum is throttle plate position. When the throttle is closed, manifold vacuum should be higher than when the throttle is open. With an open throttle it is easy for the outside air to get into the engine and there will be less difference in pressure between the outside air and the air found in the intake manifold. As the throttle plate closes, a restriction in airflow is created and manifold vacuum increases.

- A second factor in manifold vacuum is engine RPM. A slow turning engine will produce less manifold vacuum than a fast turning engine. Manifold vacuum will be at its highest when the engine RPM is high, and the throttle plate is closed. This happens when the engine is decelerating. Manifold vacuum will be lower when the engine is at starter motor cranking speeds than it will be at idle speeds.

- A third factor in manifold vacuum is engine compression. If an engine has low compression in all cylinders, it creates a steady, but low, manifold vacuum. If an engine has low compression in one cylinder, manifold vacuum will be low only during that cylinders intake stroke. This will be observed as a gauge that fluctuates or quickly changes reading. Low compression in a cylinder can be caused by leaking valves or rings, leaking head gaskets, or other ways that keep the cylinder from sealing during the compression stroke.

- A final factor affecting manifold vacuum is leaks in the air intake between the throttle plate, and the intake valves. Leaking vacuum lines, vacuum operated devices, or intake manifold gaskets are common causes for low vacuum.

Vacuum Testing

Testing Guidelines

- There are a few general guidelines that you can follow when using a vacuum gauge on gasoline engines.

- At idle, the more vacuum the better.

- The highest manifold vacuum will be on deceleration.

- A closed throttle will create more vacuum than an open throttle.

- As the engine load increases, the throttle will open wider. This will allow for more air and fuel, create more power, and lower the manifold vacuum reading.

- ⚠️ Caution! The only time you can safely run an engine with an open throttle is when the engine is under a load. This can be done using a dynamometer, or on a road test. If you attempt to leave the throttle wide open on a running engine that is in Park or Neutral, the engine RPM will quickly climb too high and damage the engine. For most engines that are running in neutral, the maximum safe engine speed is 2,500 RPM.

-

2000 rpms

- On a normal engine accelerate to around 2000 rpm and then quickly release the throttle plate. The engine should snap right back to a steady 17- 21 Hg.

-

Throttle Snap Test

- By snapping the throttle open and closed, the needle should drop to 5 inHg or lower before stabilizing at 17 and 22 again.

-

Compression Test

- If you have over 3″ of cranking vacuum, there should be enough compression to run the engine. Finding no cranking vacuum on a gasoline engine does NOT mean the engine has poor compression. Many vehicles will use an idle air control valve that opens wide during cranking.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|